Introduction

In the world of cooking, high-grade cookware is vital for chefs and home cooks alike. Behind the scenes, there is a fascinating manufacturing procedure that happens to develop the cooking equipment we utilize on a daily basis. Cookware suppliers play a vital role in this process, guaranteeing that top-notch food preparation equipment reaches our kitchens. In this article, we will certainly explore the behind the curtain operations of cookware suppliers, exploring their know-how and the manufacturing procedure they follow.

Behind the Scenes: Checking Out the Production Process of Cookware Suppliers

Cookware distributors are responsible for sourcing, generating, and dispersing different sorts of cooking area cooking equipment to fulfill consumer needs. From cookware steel suppliers to cookware kitchenware suppliers, these specialists guarantee that high-grade items reach both specialist cooks and home cooks.

Sourcing Raw Products: The Foundation of Top quality Cookware

Cookware distributors function carefully with cookware steel suppliers and other product carriers to resource high-quality resources. For example, aluminum cookware suppliers might resource aluminum from dependable manufacturers understood for their remarkable quality.

By partnering with respectable vendors, cooking equipment makers can obtain basic materials that fulfill sector criteria. This step is vital as it sets the structure for long lasting and effective cookware.

Designing and Prototyping: Bringing Ideas to Life

Once the raw materials are sourced, cookware suppliers team up with developers and engineers to bring originalities to life. They work on producing models that align with consumer preferences and market trends.

During this phase, kitchen cookware suppliers might also concentrate on integrating cutting-edge attributes such as non-stick coverings or heat-resistant manages. These improvements intend to enhance food http://zandercyyy629.trexgame.net/professional-grade-kitchenware-for-serious-home-cooks-our-top-provider-picks-1 preparation experiences for consumers.

Testing and Quality assurance: Ensuring Security and Performance

Before launching any type of product right into the market, cookware suppliers carry out strenuous testing and quality assurance treatments. They review the resilience, safety and security, and efficiency of the cookware to make certain that it meets sector criteria and customer expectations.

Cookware vendors usually partner with independent testing labs to evaluate their items. By doing so, they can supply customers with dependable and reliable pots and pans that enhances their food preparation experiences.

Manufacturing Process: Transforming Raw Materials right into Cookware

Once the style and testing phases are total, cookware suppliers progress with the manufacturing process. This procedure includes numerous actions, including shaping, molding, brightening, and constructing the kitchenware components.

Cookware steel suppliers offer the essential raw materials for this process. They make certain that the steel utilized is of premium quality and appropriate for cookware production.

During manufacturing, cookware suppliers use advanced modern technologies and machinery to attain accuracy and consistency. These modern-day techniques contribute to creating cooking equipment that heats equally, holds up against heats, and supplies exceptional performance.

Packaging and Distribution: Delivering Cookware to Consumers

After the production procedure, cookware suppliers concentrate on packaging and distribution. They very carefully package the finished products to guarantee they reach customers in immaculate condition.

Cookware established suppliers might provide various product packaging alternatives relying on consumer preferences. Some plans may include added accessories or cooking enhancers to boost the total food preparation experience.

Once packaged, cookware suppliers function very closely with distribution companions to ship items to stores or straight to customers' front doors. This reliable circulation network makes certain that consumers receive their desired pots and pans promptly.

FAQs

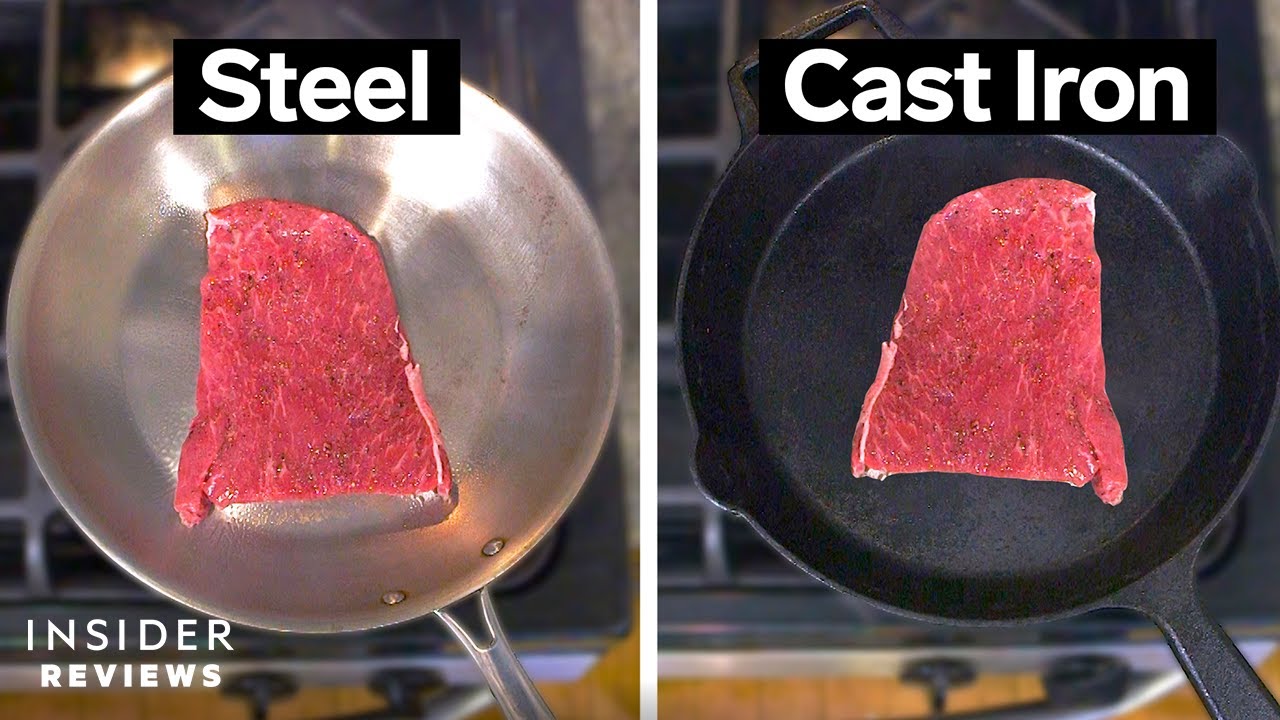

What are some usual products used by pots and pans suppliers?- Cookware providers generally utilize products such as light weight aluminum, stainless-steel, cast iron, and non-stick coatings in their products.

- Cookware vendors conduct strenuous screening procedures to guarantee the safety of their products. They follow industry requirements and work closely with independent screening labs for quality assurance.

- Yes, lots of cookware suppliers provide environmentally friendly options made from sustainable products. You can discover cooking equipment made from recycled products or those with environmentally friendly coatings.

- Some cookware suppliers supply custom layout services, enabling clients to personalize their kitchenware with specific features or branding.

- Cookware from these distributors is available via different channels, including online merchants, department stores, and specialty kitchen area stores.

- Factors to take into consideration include material quality, warm distribution, longevity, and compatibility with different cooking methods.

Conclusion

Behind the scenes, cookware suppliers are dedicated to offering first-class kitchen area devices to both expert cooks and home chefs. From sourcing raw materials to making models and conducting strenuous screening, they make sure that the items satisfy market requirements and customer expectations.

The manufacturing procedure involves shaping, molding, polishing, and assembling the cookware elements using advanced innovations. Cookware suppliers also focus on product packaging and efficient distribution to make certain that the products get to customers in beautiful condition.

Next time you remain in the cooking area food preparation up a tornado, take a moment to value the behind-the-scenes efforts of cookware suppliers. Their knowledge and dedication to high quality allow us all to delight in tasty meals prepared with reputable and effective cooking equipment.